Aluminum Composite Material fabrication is Envision's newest service offering. With the expertise we have in NMR Technology and the equipment required to fabricate ACM, we are utilizing this material to make custom enclosures, panels, signage, and other parts that lend themselves to the benefits of this unique aluminum/polyethylene hybrid material.

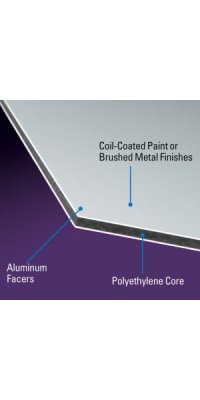

ACM's can come in different thicknesses and have varying facer thickness (see picture to below). Most often, when forming is required, Envision uses a minimum ACM thickness of .118" with facer thicknesses of .012" on each side. The reason for this is when we CNC route the ACM, it leaves some polyethylene plus the .012" aluminum facer on one side to allow for rigidity after the forming process. Thinner facers may crack. However thinner facers (such as .008") still have their advantages with flat panels such as used in some signage applications. A thinner facer allows for a lighter and more economical ACM product.

Aluminum Composite Materials offer numerous fabrication advantages which can be of great value with select applications. Take a look at our benefits page!

Envision utilizes a few different types of ACM materials such as Dibond, Signabond and Alupanel. Please see our ACM Materials Page for this information.