There are several basic design options we can apply to meet your specific plastic enclosure application.

Learn MoreCustom fabricated monitor examples using the NMR Technology include: table mount (with stand), wall mount, or even mounted to a metal chassis.

Learn MoreCustom fabricated plastic panel examples using NMR Technology include: doors, skins, shrouds, and even partial plastic housings.

Learn MoreCustom plastic fabricated bins and trays made to your specifications.

Learn MorePanels

Learn MoreEnvision Plastics and Design fabricates many types of parts using translucent materials.

Learn MoreAluminum composite material or ACM is a unique laminated material.

Learn MoreNot only do we fabricate custom plastic enclosures, we also can supply flat plates out of most any plastic extruded sheet.

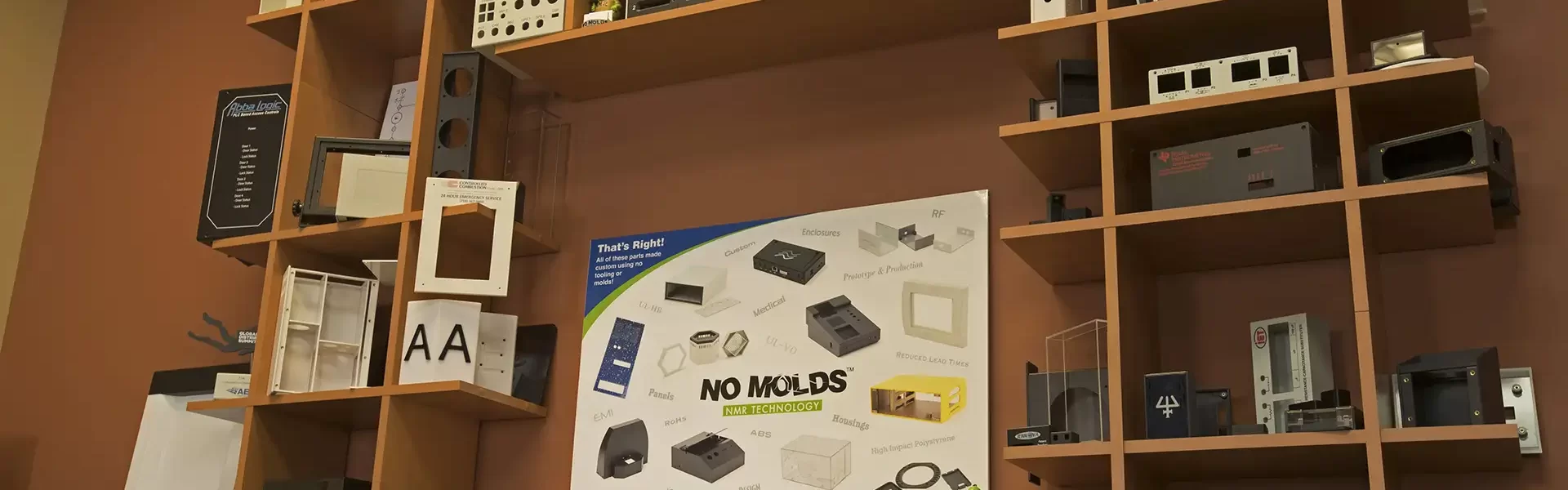

Learn MoreThere are a wide variety of custom plastic parts that the NMR Technology can produce.

Learn MoreDigital printing on our custom plastic enclosures is an additional value-add service of Envision Plastics and Design.

Learn MoreEnvision creates many custom polycarbonate plastic enclosures using the NMR Technology.

Learn MoreThe project applications above cover a wide variety of custom plastic fabrication products. Since every customer requires something different, we remain very dynamic with our design solutions to meet thier specific criteria whether it is requries a custom plastic enclosure, panel, cover, guard, or maybe even requires a specific material tpe like polycarbonate or ACM. Feel free to contact us or request a quote for your product today!

"Envision Plastics just completed a custom plastic enclosure design for us that required a housing for laboratory dispensing equipment. Envision was able to design the plastic housing using just the physical internal components we sent them, as they did not have an actual drawing from us. They were able to engineer the enclosure design by openly discussing the dimensional requirements with us regarding the features required of the design for our end use. Prior to fabrication, they showed us an animation of the housing design. We were very pleased with the attention to detail and method of communicating all aspects of the design. After receiving the prototype my exact words to the team were“I love it, great job!” "