08/25/2025

For those of you arriving at this page from an online search-don't leave! There is something here that would be good to know for future use. Conversely, if you really found something interesting here that matches your search intention, grab your favorite beverage and keep reading!

You've landed on a page within a website that describes and offers and service that is truly unique - the manufacturing of custom plastic enclosures with NO TOOLING OR MOLDS. (For more on those specifics, you can jump to that hyperlinked term in a couple minutes!)

In order to truly offer a custom solution for an electronic housing, there must be an offering of not only customizing the specific location of standoffs, but offering different variations of the standoffs themselves. Envision Plastics and Design does just that.

One of the big problems with off the shelf cases is that you are stuck with where they have thier PCB mounting locations. In addition, there are restrictions on where to attach or secure other electronic components to offer true functionality to your product. Sure, maybe you can tear some out to make room. Sure, maybe you can drill holes or add hardware after you receive the enclosure in house - but who wants that extra pain? Especially if you have left the prototyping phase and are ready to release your product to production.

Envision Plastics and Design will work with you from the onset of our project design communication to determine where standoffs need to be and if there need to be as many as you would initially expect there to be. In some cases, we are able to secure PCBs and PCB components into sidewall features allowing them the snap into place - thus reducing cost and assembly time!

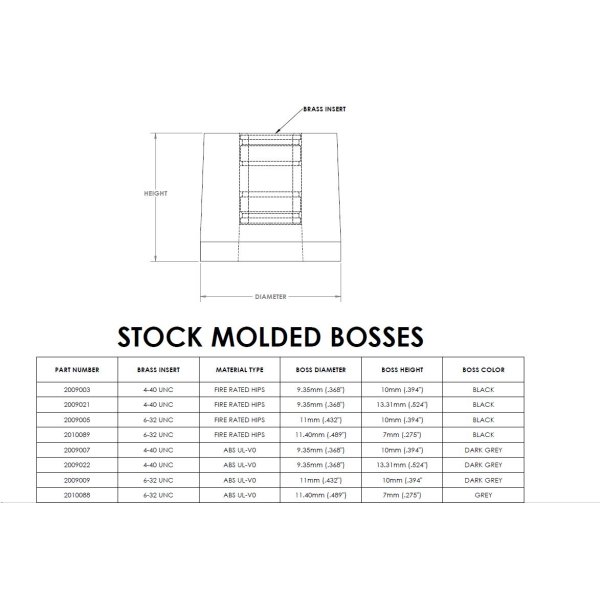

Now, I guess it is appropriate to disclose some additional truth to our 'no molds or tooling' claim above. While this is 100% true of our enclosures, we do have some standoffs of common sizes molded for us with threaded inserts in them. This really helps reduce cost and production throughput. The common standoffs we offer are below:

When we face a requirement for a standoff that does not meet our list of custom bosses, we can custom make it from thicker gauge sheet stock material though our CNC milling process. Going this route, we can make standoffs that are taller, shorter, wider, or that have a different size insert required. While it adds to cost, it can certainly be done!

Since PEMS cannot be used in plastic very well, we use brass threaded inserts in our bosses and other mounting blocks used inside the enclosures. We are also able to source inserts made from other materials (i.e. stainless) but the cost and availability may be counter productive. The other solution we offer is to not use hardware in our bosses at all! We can provide a standoff with the required hole diameter to support a self-tapping screw if that is desired.

When contacting us initially for your custom plastic enclosure project, do not worry about knowing these details prior to reaching out. Our easy design process will address that once we determine what enclosure style we are using and what components are used inside the housing.

We look forward to working with you on your next project!

"My experiences working with Envision have been great...

I had been working on a new product design with an exceptionally short deadline. We laid out the case design and sent it to Envision. When they had the parts ready for bonding for the first prototypes, I stopped by with the mating hardware and we did a dry fit. Everything lined up! I drove back with the first two cases that day.

I can’t say enough about the service Envision provided for us. They were easy to work with, met the tight time line we needed, and provided us with a quality product."

Ed, V.P. Operations Industrial Diagnostic Company