02/23/2017

Since our start in 2001, there have been numerous occasions where we have been asked to make custom plastic battery enclosures, plastic battery housings, plastic battery covers, and other plastic fabricated parts associated with batteries. Although we can't make intricate battery cradles so to speak, we surely can integrate removable access panels into our plastic enclosure design to support the use of replaceable batteries.

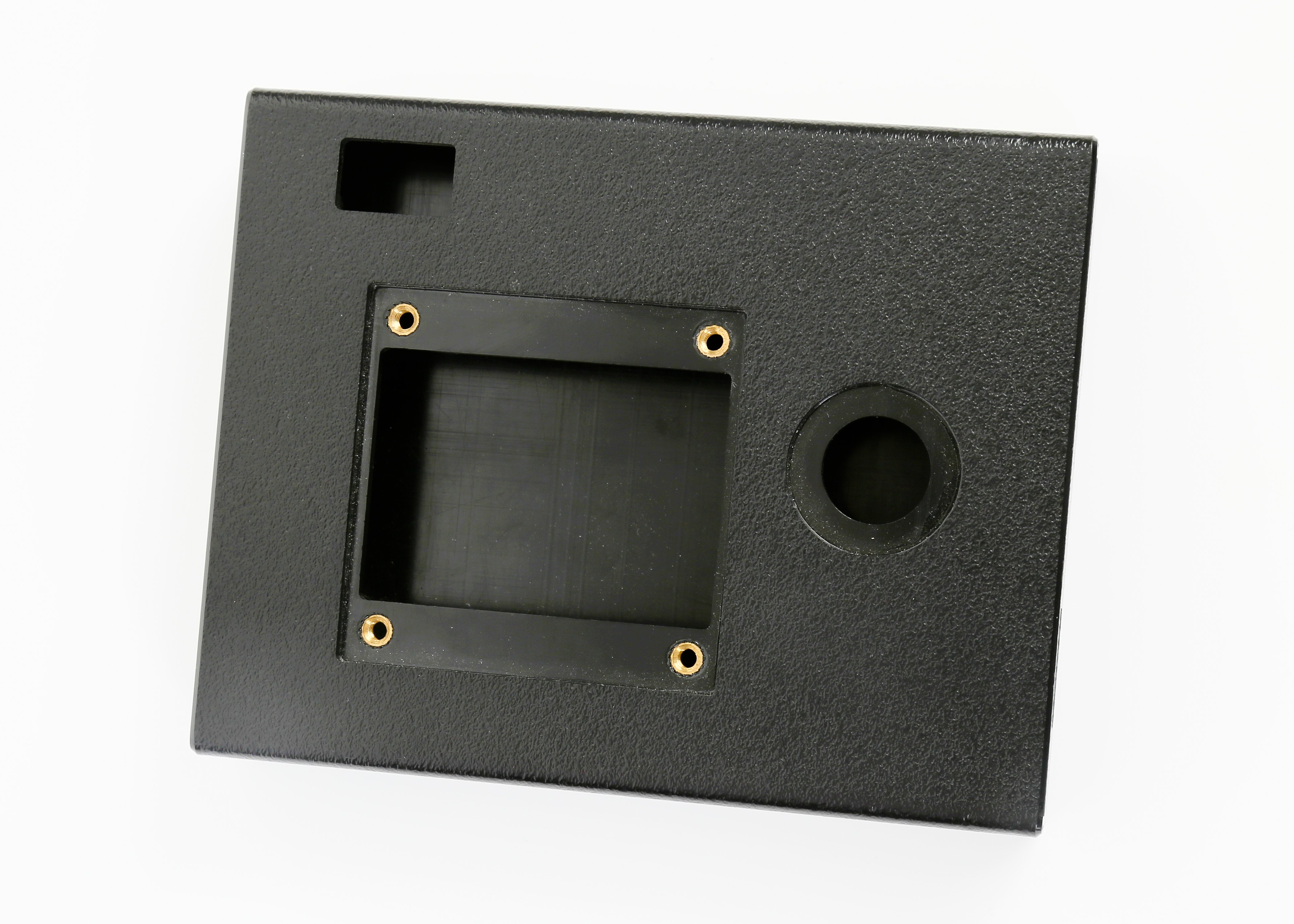

In fact, one of our newer project opportunities involves a custom plastic battery box that requires a weatherable material (R85/21), removable cover, gaskets to serve as a protectant against dust and water, and easily removable screws. In addition, battery leads and connectors must also be in place. Envision's NMR Technology usually does not get very intricate with battery holding mechanical requirements, however we may utilize an off the shelf battery holder to aid in securing the batteries inside the custom plastic housing. This cradle device would also (most likely) have the connectors needed to draw power from the batteries. As far as the rest of the functionality requiurements go - making weatherable enclsoures with a removable cover is a piece of cake. Many enclosure designs ship out of Envision on a monthly or even weekly basis meeting that electronic enclosure qualification.

More recently, we have received inquiries of making custom plastic fabricated battery covers. These plastic covers are mostly for the automotive or marine type battery where plastic material is used to protect the battery and fasten to the main frame which holds the battery. Due to the lower volume of the vehicles or boats which require this, the No Molds Required fabrication method presents the perfect solution to this application!