04/08/2019

Plastics are used in every industry as they provide versatile options and have a wide range of applications. However, each application requires a manufacturing process to create each plastic part and those processes are definitely different.

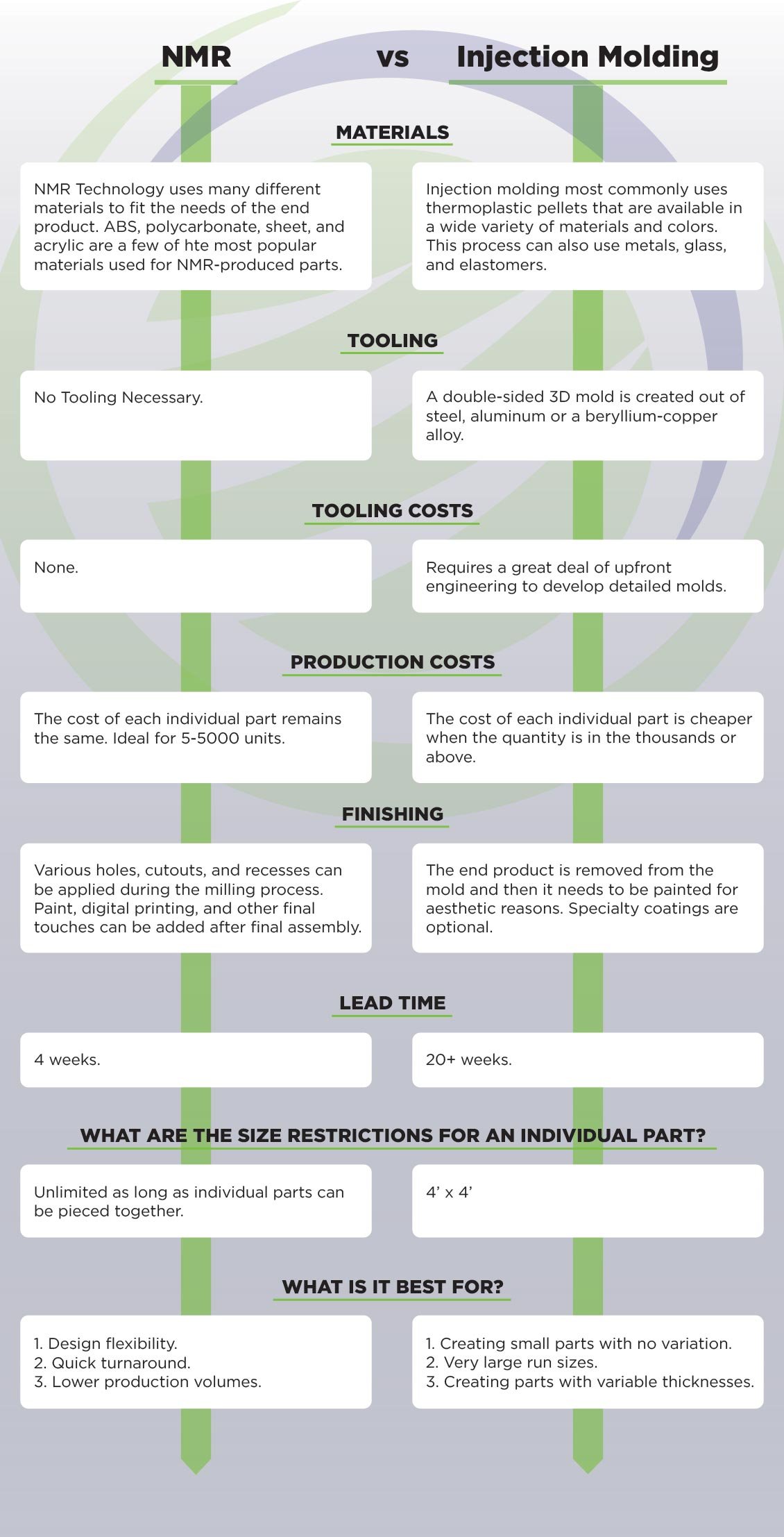

No Molds Required technology and Injection Molding are very common manufacturing processes for creating plastic parts. We’ll dive into the differences to help you better understand each process so you can make a decision that is best for your project.

No Molds Required (NMR) Technology is a unique plastic fabrication method used to create custom plastic parts. Just as the name says, no molds are required and no tooling is necessary to create a plastic enclosure, box, housing, panel, shroud, tray, or other plastic parts. This process combines plastic fabrication with elements of woodworking (tongue and groove) and sheet metal crafts.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. This process can be performed with a number of materials that are heated prior to being injected into a mold where the product cools and hardens to the desired shape. Injection molding is used to create many items and is ideal for mass production that requires thousands or millions of the same part.

Choosing the right process can be difficult, especially if you lack familiarity with these plastic fabrication methods. If you are unsure of what process is right for your project, give us a call, we are here to help.